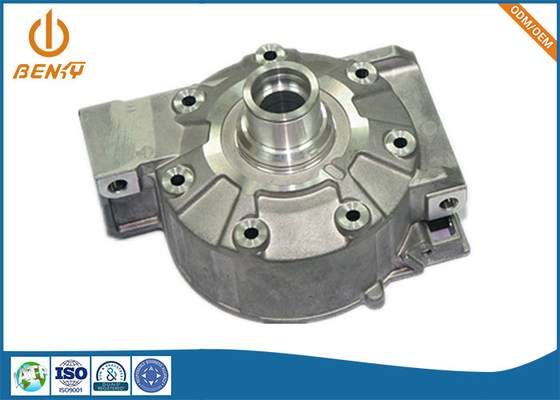

A380 Casting Automotive Parts For Air Conditioner Compressor Housing

Aluminium Die Casting Machinery Parts OEM Aluminium Die Casting For Auto Parts Air Conditioner Compressor Housing

Established in 1990, Shenzhen Benky Industrial Co., Ltd. The company specializes in Die casting mould , designing tool and fixture, machining of e-bike motor parts, e-scooter parts and precise gear hobbing. The company not only establishes a stable strategic relationship with domestic first-class motor companies, but also exports to Europe, United States, Japan and other countries.

We have obtained the certification of many international standard systems such as IS9001, ISO/TS16949, EICC, and Dun & Bradstreet .

Our annual capacity of die cast is 30,000 tons and our annual capacity of molds has exceeded 300 sets. We have more than 40 die-casting

machines ranging from 280T to 4000T, and the largest casting weight can be 50KG. We also have more than 200 CNC machining centers.

Pursuing breakthroughs with reforms, promoting improvement with innovations; seeking development with quality, building brands with integrity; winning customers with service and promoting development with win-win are the values that our company has always adhered to. Our company is always committed to providing customers with higher quality products.

![]()

![]()

Q1. Are you a factory or trade company?

A: We are a factory with over 30 years in die casting and CNC machining. We service customers aluminum die casting ,mold design, die casting, machining and Product assembly.

Q2. Where is your factory?

A: Our factory locates in Shenzhen china, 45 minutes drive to Shenzhen airport, 1.5hs drive to Hongkong

Q3:Available for customized design drawings?

A:2D(PDF/DXF/DWG fomat file)3D(IGS/STEP format file)

Q4:How to know the production process ?

A:We will send digital pictures and videos show you the production process

Q5:Do you provide samples ?

A:Yes , we could offer the sample for customer to check quality and specification.

Q6:Will my drawing be safe after you get it?

A:Yes , we can sign the NDA before you send the drawing.

Q7:What is lead Time for order?

A:In General , For sample , it is take about 10 days , and for mass production, it Is take 30 days.

Q8:What`s the MOQ ?

A:5piece sample , we accept sample order for customer to check quality ad specification.100pcs/batch.

Q9. Payment terms

A: Mold costs: 40% prepay upon order confirmation, balance after sample approval Mass production: 30-50% prepay, balance upon B/L available.

Thank you for your watching!!!