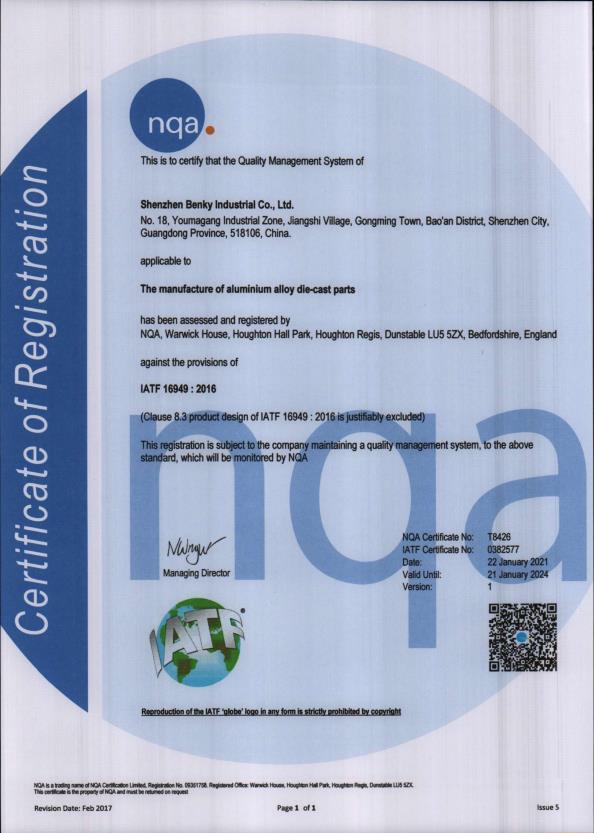

Shenzhen Benky have obtained the certification of many international standard systems such as IS9001, ISO/TS16949, EICC, and Dun & Bradstreet certification.We are specialized in diecasting parts in past 30years. We have full-automatic diecasting machine from 188t to 4000t, 15,000m 2 die casting workshop, various CNC machining equipment. We are familiar with various surface treatment which have electroplate, Powder coating, anodized, high Polishing, Shot blasting, Sand blasting so on…

The company′s lead products are aluminum alloy New energy storage,New energy vehicles,LED radiator, lighting fitting, phone accessories, connected parts, motor shell, hardware, auto parts series, mould design etc… We always supply the best solution and top quality to our clients.We stick to the principle "quality first, service first, continuous improvement and innovaion " to meet our customer′s satisfaction, offer complete Die-casting.

| Item Name | New energy vehicles,Communication,Home Appliances,Etc Aluminum Alloy Housing Die Casting |

| General Products,Application/Service Area | Metal Parts Solution for New energy vehicles,Communication,Home Appliances, Agriculture machine, transportation equipment, Agriculture machine metal Parts, etc. |

| Certification | ISO9001:2015, IATF16949:2016 EICC,Dun & Bradstreet and RBA certification |

| Process | High-pressure die casting,Aluminum Sand Casting,CNC Machining,Finishing Services |

| Blanks Tolerance -Casting Tolerance | ISO 2768 m for Permanent Molding, Die Casting, |

| High Pressure Die Casting Material | A380/A390/A360/ADC10/ADC12/Alsi7mg/Alsi12/ENAC-43400/ENAC-44300/ENAC-44400/ENAC-46000/EN Alsi7mg |

| Low Pressure Die Casting Material | A356/A357/A319/A413/ZL101/ZL102/ZL104/ZL107/LM6//LM/20/LM25/EN AC-42100/EN AC-42200/EN AC-43000/EN AC-43200/EN AC-43300/EN AC-43400/EN |

| CNC Machining Material | AL6061/Al6063/AL6082/AL7075/AL5052/A380 |

| Casting Blank Size /Dimensions | 2 mm-1500mm / 0.08inch-60inch , or according to customer requirements |

| Casting Blank Weight | From 0.02- 50 Kg for Die Casting Process |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ |

| Broaching/Reaming /Grinding/Honing and etc. | |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

| Applicable Heat Treatment | T5~T6 |

| Applicable Finish Surface Treatment | Zinc/Brass/Chrome/Nickel Plating, Polishing, Mirror Polishing, Painting, Powder Coating, E-coating, Anodizing, Pad printing, Silk Screening |

| Inspection Facilities | Spectrograph, CMM, Resin Sand Analysis Device, X-Ray Detection Eqipment, Leak Test Equipment, Hardness Test Device, Meallography Analysis Device, Salt Spray Test Chamber, etc. |

| Quality | 100%inspection before shipping |

| MOQ For aluminum casting | For sample 5piece,Small batch 100piece |

| Die casting equipment specifications | 250T-4000T 50sets |

| CNC processing equipment | 200 sets |

| Lead Time | CNC For sample10days,Die Casting for mould 25-50 days,for mass production it Is take 30 days. |

| Standard | ASTM, DIN,JIS, EN, ISO, GB |

| Software | Pro/E,UG, Solidworks, Auto CAD |

| Payment Methods | T/T, L/C, West Union, Paypal |

FAQ:

Q1:Are you manufacturer?

A:Of course we are.We Have our own factory.We accept customization.Our company located in Shenzhen city where is the most large mold base.

Q2:What's your lead time?

A:Mold manufacturing time:It depends on the product size and structure, usually the mould making lead time is 25 to 35days,die casting production time;according to the steps and complexity of product processing,and the quantity of the order

Q3:How to control the quality?

A:We have QC department,three-coordinate measuring machine,projector,high gauge etc in mass production stage,we will have the professional QC and die casting and plastic injestion engineers to control the product quality,test 10pcs each hour.

Q4:What Surface finishing can your provide?

A:We can provide shot blasting,polishing,painting,powder coating,anodizing,electroplating,Chrome Plating(Matt/Bright),Nickle plating,Zinc Plating,mirror polishing,trivalent chromate passivation,e-coating,etc.

Q5:Do you provide prototyping service?

A:We can help you with your protoyping needs and expecting the high volume production.

Q6:If I send you the 3D file,why do you still need 2D drawing?

A:The 3D file is very useful,but there are some ohter requirement not indicated like the toler-ance and the sueface treatment apply in the part.This is why the 2D file is needed

Q7:What other qusetions can I get the fast quotation?

A:The annual quantity,materials selected,application or function of the parts,project delivery schedule,net weight(if you don't it,you must give us the 3D file),destination port.

Q8:What materials Saige offer?

AlSaige offer Aluminum And Zine Alloy for die casting.For example ADC12,ADC6,A380,AlSi12Cu1(Fe),AlSi9Cu3,etc.

Our services cover all industries and reach all parts of the world.We can make all kinds of products for you according to your design.